From the first proof-of-concept of a cultured-beef burger in 2013, to chefs serving cultured-chicken nuggets in a Singapore restaurant in 2020, this nascent industry is developing at an impressive pace.

Worldwide, more than 60 startups have embarked on the exciting journey of producing animal-based products from cell cultures. Additionally, several companies are working exclusively on certain technical aspects such as growth media and bioreactors.

Worldwide, more than 60 startups have embarked on the exciting journey of producing animal-based products from cell cultures. Additionally, several companies are working exclusively on certain technical aspects such as growth media and bioreactors.

Salmon, lobster, bacon, meatballs, chicken nuggets, ice-cream, cheese, gelatin, and egg proteins – food-tech companies are developing many of the animal-based products that most people know and love as cultured products.

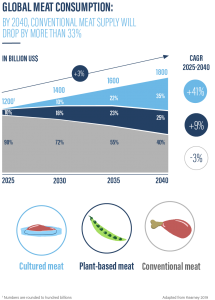

These products have the potential to help mitigate many of the world’s most challenging problems. They are also capable of taking on a substantial share of the protein sector in the coming years. According to the consulting firm Kearney, cultured meat could constitute 35% of global meat consumption by as soon as 2040.

As a complement to the increasing number of plant-based products available on the market, cultured products could play a major role in achieving ProVeg’s mission of 50by40. Which is why Proveg initiated the CellAg Project in 2019, with the aim of raising awareness of cellular agriculture in order to pave the way for a fair and objective reception of cultured products.

Cellular agriculture: processes and expected benefits

Cellular agriculture currently comprises two different approaches: cell cultivation (cellular) and precision fermentation (acellular).

The cell-cultivation method

The cell-cultivation method refers to growing meat directly from cells. Cells are the building blocks of all life. By cultivating them to produce meat, fish, and seafood, we can avoid raising of animals for food. In order to produce meat and seafood, stem cells are first sampled from animals via a biopsy.

These cells are then fed with nutrients in large vats, known as cultivators, where they multiply and differentiate. As they grow, they become muscle tissue, which is the main component of meat. A number of startups and companies are currently working to develop a variety of cultured foods. This includes beef, pork, chicken, fish, and seafood.

The precision-fermentation method

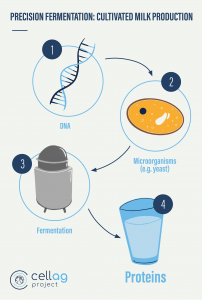

The precision-fermentation method refers to the use of microorganisms rather than cell cultures to produce milk or egg-white proteins.

These products can be grown directly from microorganisms which are introduced into microflora such as yeast. The fermentation process is similar to that which humans have used for many years to produce enzymes such as rennet and vanillin. Rennet is a key ingredient for making cheese, while vanillin is the main component of vanilla flavor.

These products can be grown directly from microorganisms which are introduced into microflora such as yeast. The fermentation process is similar to that which humans have used for many years to produce enzymes such as rennet and vanillin. Rennet is a key ingredient for making cheese, while vanillin is the main component of vanilla flavor.

Startups and other companies are currently working on developing milk, ice cream, cheese, gelatin, and egg whites in this way. Legendairy, a startup from Germany that took part in the ProVeg Incubator programme in 2018/19, is the first European startup to develop milk and cheese via precision fermentation.

Another ProVeg Incubator alumnus, Remilk, is also developing milk proteins for producing safe and delicious dairy products.

Products from other companies have already been commercialised in the US, including the Perfect Indulgence ice cream product, which uses Perfect Day’s flora-based dairy proteins, and Clara Foods’ animal-free pepsin, which will be distributed by Ingredion, a leading ingredient provider.

Blending plant-based and cultured ingredients: the potential of hybrid products

Hybrid products combine plant-based and cultured ingredients to develop tasty and sustainable products that are also cost-effective. This new product category is promising in terms of texture and taste, while adding an appealing juiciness to plant-based alternatives.

For instance, adding cultivated fat to a plant-based chicken nugget could provide the familiar taste of animal-based chicken, as well as improving juiciness and meatiness. It would also have an authentic texture, thanks to the plant-based proteins.

Looking at it this way, plant-based and cultured products are not mutually exclusive categories. They actually form a highly promising complementary strategy. Together, they have the potential to accelerate market entry by combining two approaches to arrive at a perfect result.

Benefits of cellular agriculture

Cultured products have the potential to be safer and healthier than conventional animal-based products. With no animal husbandry involved, the food industry could vastly reduced risk of contamination from pathogens such as Listeria, E. Coli, or Salmonella, as well as a decrease in zoonotic diseases such as mad cow disease, swine flu, avian flu, and COVID-19.